Cooperate with us:

Value-Added Exclusive Distributor of industrial technologies

Industrial Hub &

Competence Center

Industrial Technology

Collaborative Designer

We supply smart technology solutions for diverse industries

Automation

machine systems

We provide comprehensive solutions in the field of industrial automation – catering to both original equipment manufacturers (OEM) and system integrators. Our products come with mostly 1-2 years of warranty and technical support.

Our offer encompasses a full range of automation equipment not only for simple machines but entire manufacturing lines and processes. This includes system power supplies, motion control devices, systems for industrial communication and process visualization, and operator interfaces for control systems. Our online store offers the convenience of ordering components quickly at any time.

Check products in our offcial online store

- Process automation and control

- Industrial communication

- Motion systems

- Redundancy systems

- Safety systems

- Visualization of processes

Industrial software

and maintenance / Optimize (PI)

For over 28 years, we have assisted our clients in digital transformation, delivering intelligent technologies based on solutions provided by AVEVA, the global leader in industrial software. You can rely on our expertise both in continuous and discrete manufacturing processes, as well as systems for critical infrastructure and heavy industry.

Together with a network of over 200 partners, we provide industrial software, expertise, consultations, training, and full technical support, both before and after implementation. The AVEVA solutions enable us to scale facilities of every size through process optimization, utility monitoring, and process control (SCADA / MES), along with advanced management of business processes (Control Room, Productive Maintenance, Digital Twin, AI).

- HMI / SCADA systems for process visualization and control

- MES for manufacturing management

- Systems for utility and power efficiency monitoring

- Control Room systems

- Systems for reporting and data analysis

- AI for Industry

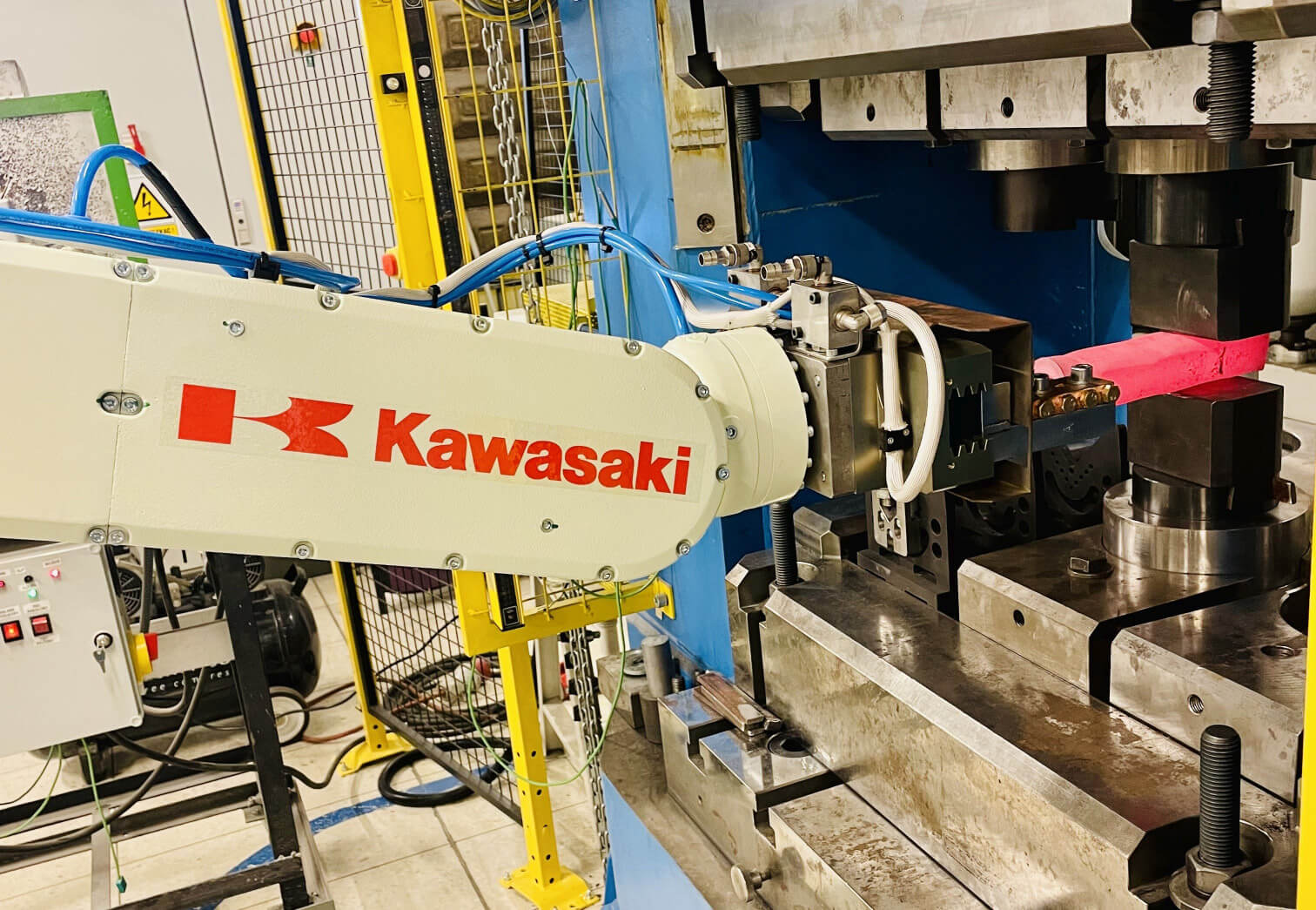

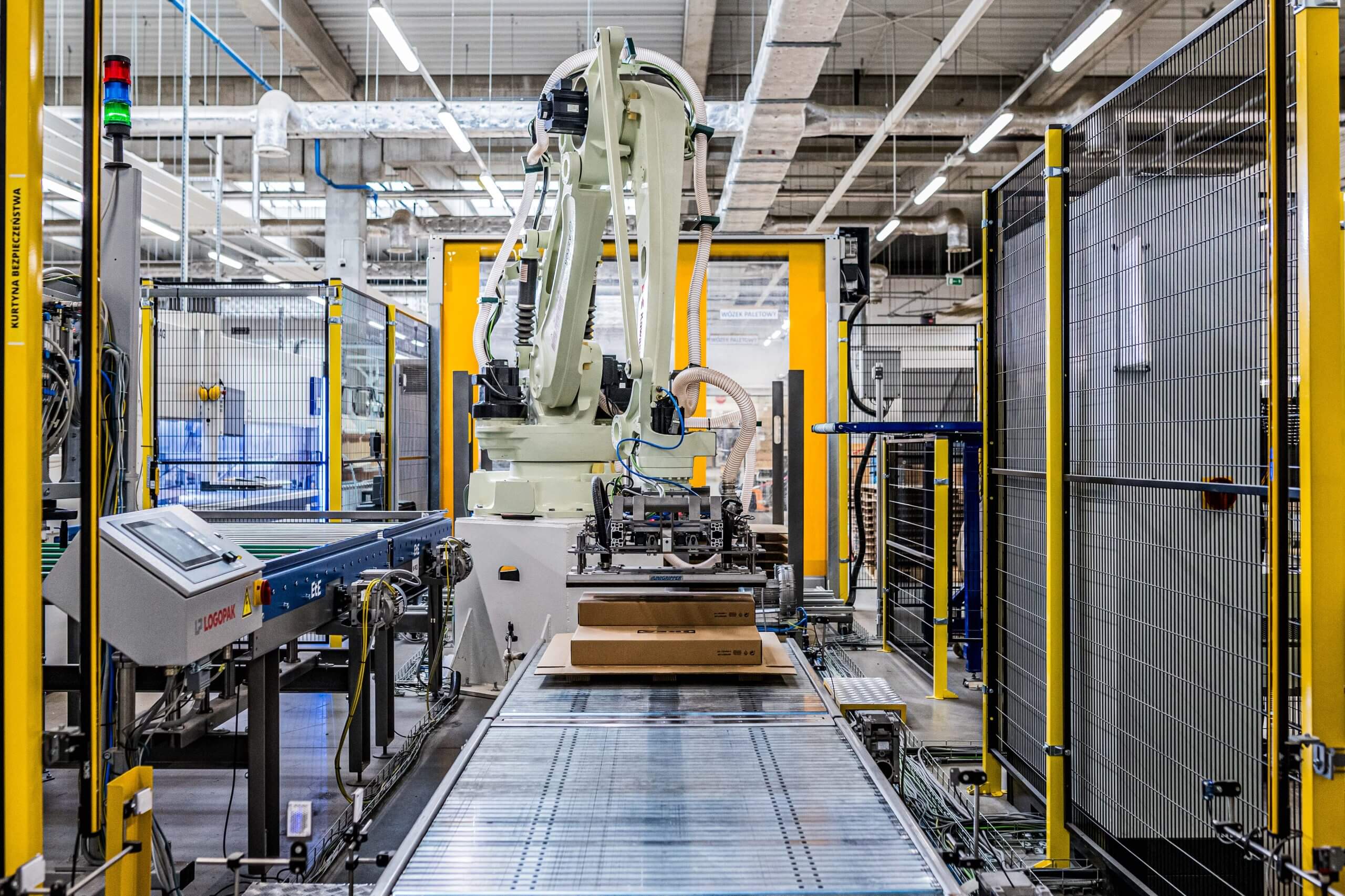

Robotization

We specialize in delivering a comprehensive range of robotic solutions, including industrial robots and cobots, application equipment, automation systems for robots, and complete robotic stations

In our offer, you will find industrial robots and cobots designed for palletizing, welding, machine operation, painting, varnishing, and various other applications. In addition, we provide robotic equipment, featuring linear tracks, positioners, sensors, safety curtains, HMI panels, and complete robotic stations.

Beyond hardware, our services extend to business and technical consulting, audits, training, and authorized robot servicing. We specialize in software solutions for robotic production lines, integration with ERP and WMS systems, and monitoring for robotic stations. Furthermore, we warmly invite you to take part in live demonstrations and tests conducted in our two ASTOR showrooms.

- Robotized palletizing and packaging

- Robotic welding

- Robotic machine operation

- Intralogistics with mobile and industrial robots

- Cobots (collaborative robots)

- ASTOR Robotics Center showroom

- ASTOR Innovation Room showroom

Intralogistics

cells and systems

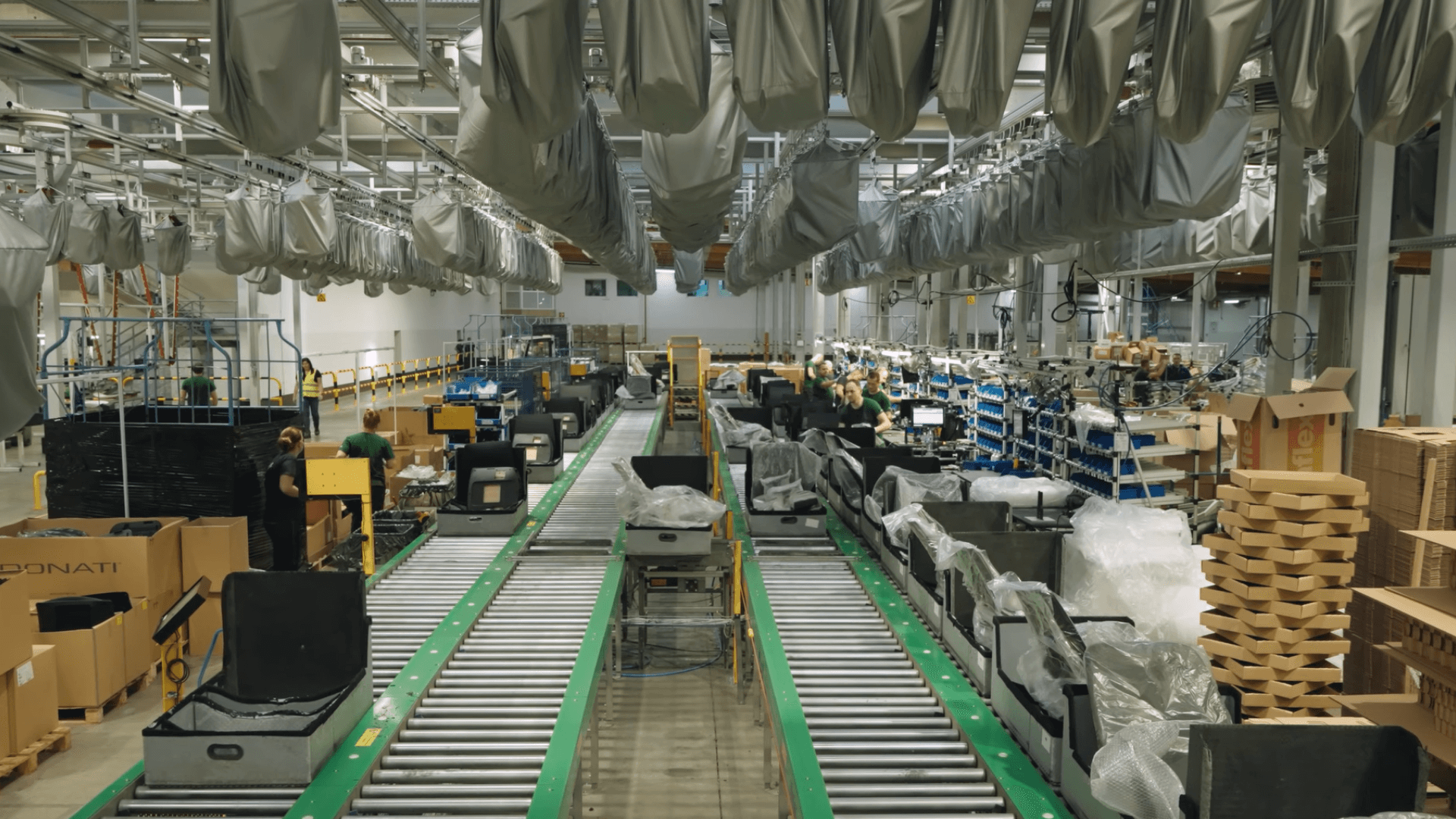

Intralogistics – the bloodstream of the manufacturing process.

Intralogistics is the fine art of optimizing, integration, automation, and the management of material flow within a company. Modern on-site transportation forms the core of manufacturing process control, as it connects various manufacturing areas and sets the rhythm for the whole production.

For the last 10 years, ASTOR has been developing projects and delivering automated logistics systems, mainly for manufacturing processes. Expanding our offer to include autonomous mobile robots like AGILOX has allowed us to implement intelligent intralogistics projects more effectively.

We provide proper project coordination and support in investment management, keeping in mind that every manufacturing process is unique. We organize and conduct investment processes End-to-End, from initiative to implementation.

- Intelligent intralogistics

- Autonomous mobile robots (AMR)

- Autonomous forklifts

- Intralogistics with mobile robots

- On-site transportation systems

Years of experience

Automation, robotization, digitalization and intralogistics systems

Trained engineers

Employees

We have reached these goals thanks to the companies that have trusted us.

Active System Integrators

System integrators, i.e. implementation companies to whom we address our Partner Program, and OEMs, i.e. manufacturers of machinery and equipment for various industries

End Users and Machine Builders

End users, i.e. industrial plants, manufacturing companies and public infrastructure units.

Universities and technical schools

Distributors, i.e. companies developing product sales, marketing and technical support for other companies, i.e. Partners and End Users

What do our customers say about us?

Inspire yourself with success stories of our customers

35 years of ASTOR’s history means the trust of more than

9,000 of SMEs, large and global corporations,

where 50,000 of our intelligent systems and solutions are in operation.

…and many others, large, medium and small companies